Quality Throughput Profitability

2-week Diagnostic 20-week Project

Operational Excellence Industry 4.0

THE OPPORTUNITES

Produce high quality products by maintaining consistent standards specifications in order to increase capacity in a modernized plant with several productions lines, while contributing to waste reduction and significant increases in productivity and profitability.

The global Supply Chain disruption caused the client’s demand to dramatically increase. Being a preferred local supplier, the plant needed to rapidly improve throughput to deliver increased customers’ demand.

Adding to that challenge, waste levels were high, non-controlled quality issues and clients claims were affecting the overall business performance.

Although, there was a recent investment on machinery and modern equipment, elements were missing from a robust Target Operating Model to Plan, Execute, and Monitor operational performance and develop consistent quality products.

Utilization of installed capacity was not optimized to meet growing market demand.

Performance Management Operating Model was unclear, resulting in limited real time performance.

Need to focus on preventive and predictive maintenance plans – Maintenance team was mainly reactive.

Need of Industry 4.0 applications & Digitalization: KPIs, reports, data collection & automation.

Formal agreements between commercial and production areas were unclear generating ‘last minute’ changes in the weekly production schedule.

Due to the high cost of raw material and difficulty obtaining it, waste became critical to lower.

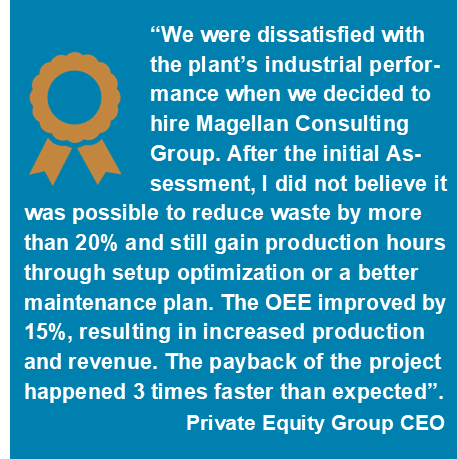

Monofilament Yarn Company increased production by 25% and reduced waste by 28%

APROACH AND OUTCOMES

QUALITY

Implemented a robust operational model to plan and monitor, in real time, Key Process Indicators to support decision making based on facts & numbers, eliminate root cause of endemic quality problems – daily & weekly management routines.

Reviewed Routing Adherence management process and reporting to create and implemented an automated SOP for changes.

Redefined critical daily automated KPI’s – creating the foundation for a digital and analytical cultural mindset to problem solving. Systematic process review on main causes of quality issues.

INDUSTRY 4.0 & DIGITALIZATION

Fully automated Operational and Executive Management Reporting & Dashboards directly connected to company’s ERP systems – elimination of spreadsheet as analysis and reporting tool – ‘No Excel left behind’.

Developed ERP capabilities to accommodate digitalization initiates such as fully eliminate paper based process monitoring and manual data collection. Direct input of quality and production information in the ERP system.

PRODUCTION & OPERATIONAL PLANNING

Reviewed production capacity by setting up a Master Schedule type per product and market to increase throughput.

Developed preventive maintenance plan for critical equipment and inspection routines by line.

Optimized Setup Time, through the applying SMED principles and created a Sequencing Matrix to help identify and implement a streamlined process for minimization of Setup Time.

Streamlined and automated the Planning & Scheduling process and developed SLA’s with Commercial Area.