Performance 4.0

Advanced Industry 4.0 Platform

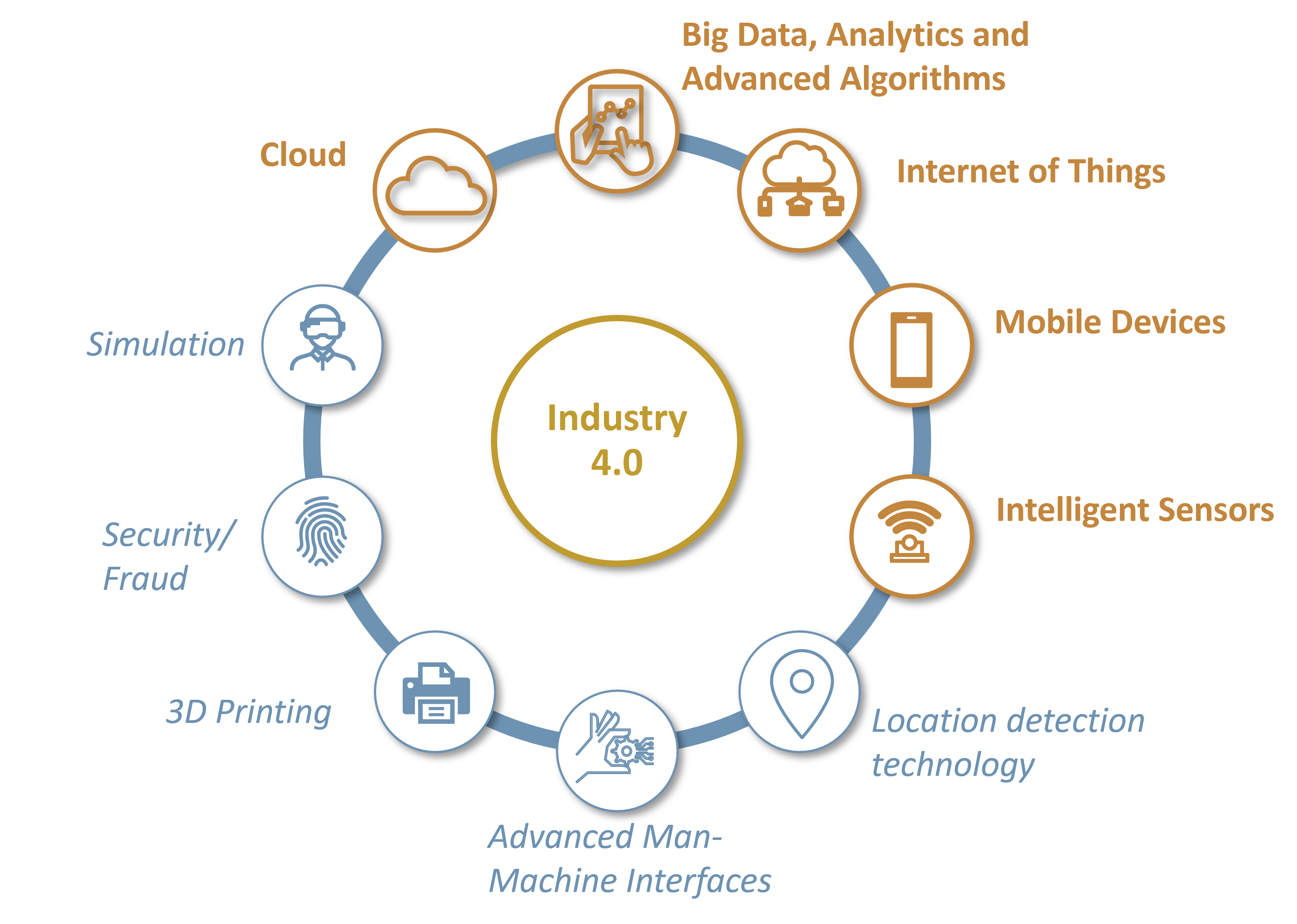

An advanced machine learning algorithm analyzes process data collected from production systems to provide alerts for early-stage anomalies and system failures to predict product quality

The Internet of Things refers to a technological revolution that aims to connect everyday used items to the world wide web. Predictive maintenance is a focus for the Internet of Things in Industrial Manufacturing

With applications installed on mobile devices that communicate with the systems that industrial automation establishes, it is possible to have access to production data, failure statistics, predictive maintenance schedules, task control, produce reports at the end of the day and much more.

Cloud systems in Industry 4.0 allows for greater efficiency, automation, and data-driven decision making in manufacturing and industrial processes. It can also enable new business models and create new opportunities for innovation.

Intelligent sensors play a crucial role in Industry 4.0 by providing real-time monitoring and data collection of industrial processes, being used in a variety of applications, such as quality control, predictive maintenance, and process optimization.

Industries 4.0 applications commonly implemented in our clients' engagements

OEE Automation

Artificial Intelligence

Systems Integration

Machine Connectivity

Data Automation

Streaming Analytics

Predictive Maintenance

Internet of Things

INDUSTRY 4.0 ASSESSMENTS

EVALUATE YOUR CURRENT INDUSTRY 4.0 AND PREDICTIVE MAINTENANCE MATURITY AND GET A CUSTOMIZED REPORT

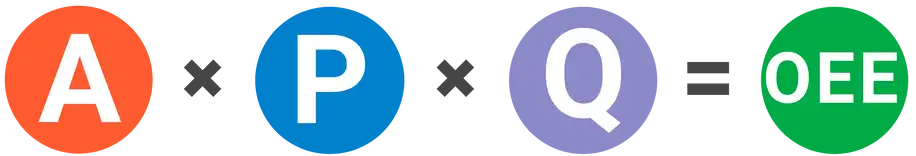

Performance 4.0 & OEE Optimization

Availability

Performance

Quality

Performance 4.0 is key to improve OEE since provides valuable automated data that can be used to improve operations to the next level of performance

Using IoT sensors and machine learning algorithms, Performance 4.0 enables predictive maintenance, allowing organizations to detect and prevent equipment failures before they occur, reducing downtime and improving availability.

Performance 4.0 allows for real-time monitoring of production processes, providing valuable insights into performance and identifying areas for improvement.

By analyzing data from production processes, Performance 4.0 enables organizations to optimize their operations, reducing waste and increasing production speed.

Using AI and machine learning algorithms, Performance 4.0 allows for real-time quality control, reducing the number of defects and improving product quality.

Performance 4.0 provides real-time data, allowing organizations to make informed decisions that optimize production processes, improving OEE and overall efficiency.

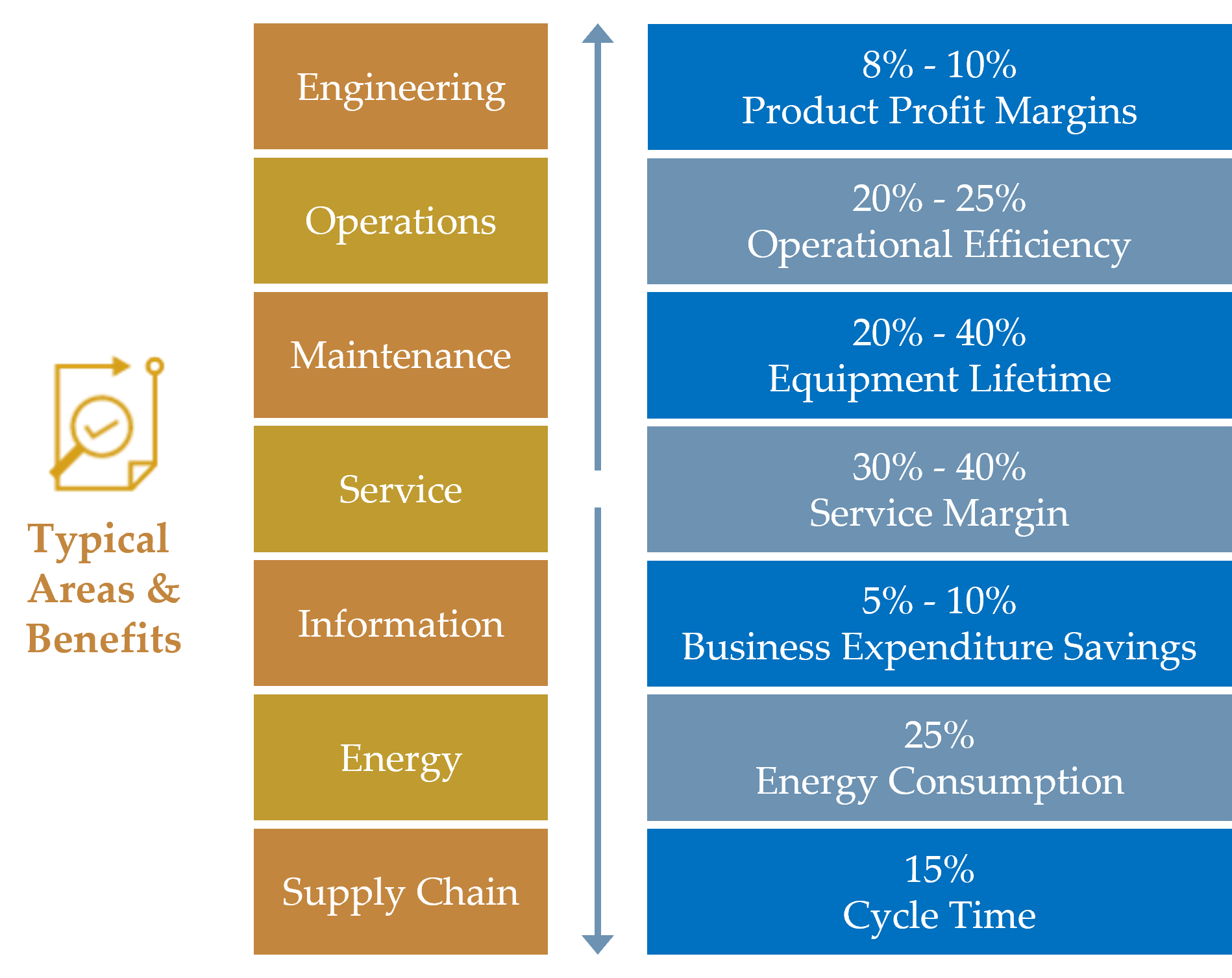

Performance 4.0 Benefits

Efficiency & Effectiveness

Automation & Digitalization